Smart Warehouse Solution

Smart warehouse is a concept that processes a management via smart logistics and information collecting, Internet of Things, cloud computing and mechatronics, thereby reducing warehousing costs, improving operational efficiency, and enhancing warehousing management capabilities.

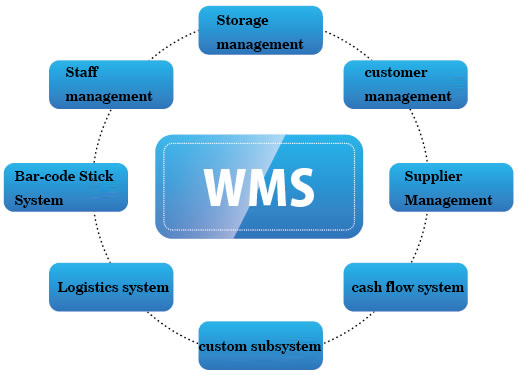

The warehouse management system standardizes and systemizes operations such as parts in-out, picking, and real time inventory and also provides management functions such as storage location management, expiration date and packing number control, material tracking and query, and various resources in the warehouse to optimize the efficiency of warehousing operations. Global enterprises are actively promoting the concept of "smart factory", and generally consider adding automatic sensing equipment, decision-making and software execution to reduce the loss of human operation. In addition to providing various cloud-integrated hardware devices, APPOSTAR provides specialized and customized highly integrated smart systems based on these concepts. The APPOSTAR professional team suggests you to consider the following automation equipment,

1. Automatic storage warehouse establishment

2. AGV automatic guiding robot setup

3. Automatic conveyor line

4. Smart human interface computer

Smart Warehousing

In recent years, our country's logistics industry has developed rapidly, among which the automated three-dimensional warehouse is a typical representative. According to the cargo access form of the automated three-dimensional warehouse, it can be simply classified as:

1. Shelves with digital connection warehouse

2. Shelves with rack warehouse

3. Automatic mobile rack warehouse

4. Fully automated warehouse solution

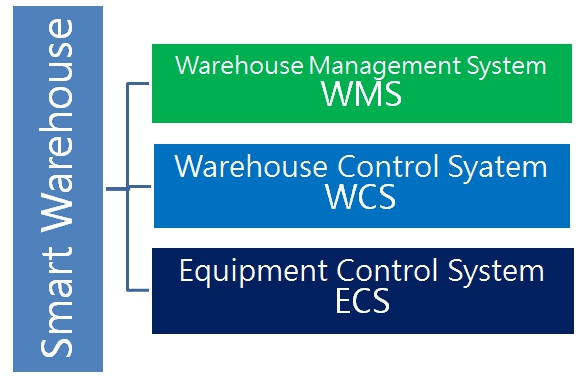

Software and Hardware Structure

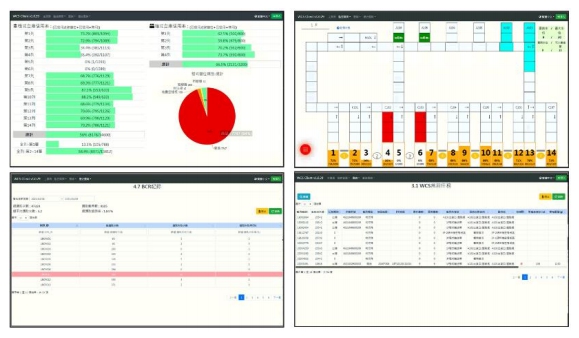

Warehouse Management System (WMS)

Warehouse Control System( WCS )

WCS (Warehouse Control System).It is an execution unit under the automatic warehousing communication control system, which is defined to receive the instructions issued by the WCS and drive the equipment to perform actual handling behaviors in the logistics process. The WCS is located in the middle layer between the WMS and the logistics equipment, and is responsible for coordinating and scheduling various logistics equipment. The ECS is located at the lower layer of the WCS and performs the actual tasks of the equipment. The equipments are used to carry out goods to work such as storage handling and production jobs material preparation.

Equipment Control System( ECS )

It is an execution unit under the automatic warehousing communication control system, which is defined to receive the instructions issued by the WCS and drive the equipment to perform actual handling behaviors in the logistics process. The WCS is located in the middle layer between the WMS and the logistics equipment, and is responsible for coordinating and scheduling various logistics equipment. The ECS is located at the lower layer of the WCS and performs the actual tasks of the equipment. The equipments are used to carry out goods to work such as storage handling and production jobs material preparation.